Research into the flow field around the nose landing gear and doors of an A350 aircraft to determine the unsteady aerodynamic loads generated by the turbulent flow.

Turbulent flow around the doors and nose landing gear of an A350 can lead to large fluctuations in the aerodynamic forces on the doors. These unsteady loads can lead to problems opening the doors and deploying the landing gear. Computational fluid dynamics (CFD) is used to calculate the flow field around the landing gear and doors to determine the unsteady forces and the results are compared with the wind tunnel tests. The methods used and developed in this project will help to improve the design of future landing gear systems.

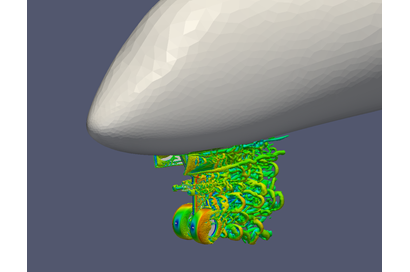

A CFD simulation of the A350 nose landing gear has been done using OpenFOAM software. The mesh has been constructed in Gridgen using a hybrid grid strategy which resulted in 54 million cells for the complex nose landing gear geometry. Detached Eddy Simulation was used as the turbulence model for the separated flow around the landing gear. The flow field has been post processed using ParaView to show the characteristic flow features. The CFD results show good agreement with the measurements in the wind tunnel which means that this is a reliable method to predict the unsteady loads on such a complex geometry.

Turbulent flow structures around the nose landing gear

Grid slice and pressure distribution on the fuselage and nose landing gear